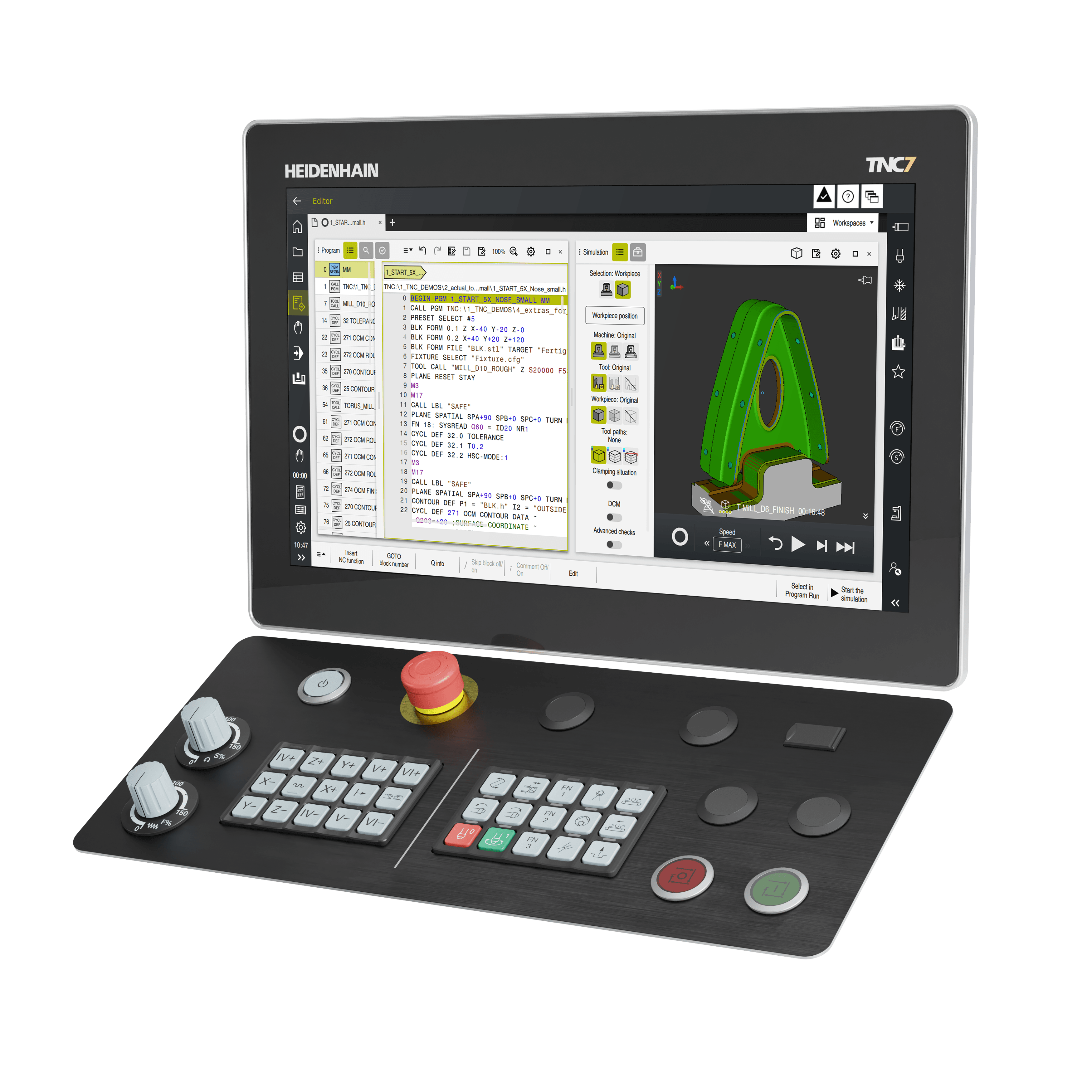

Sustainable manufacturing with the TNC7

Software options for 6D setup support allow TNC7 users to probe fixtures and workpieces up to five times faster, thus saving considerable time and energy. Thanks to the non-stop monitoring of components and processes, along with extensive simulation capabilities, the TNC7 increases the process reliability of machine tools.